What's Worth More: A Cow's Milk or its Poop?

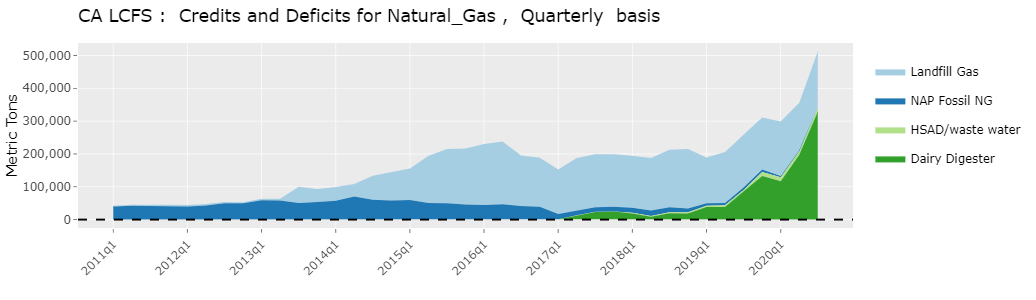

Anaerobic digesters turn cow manure into biogas. Like natural gas, biogas is mostly methane, so it can substitute for natural gas in electricity generation and powering vehicles. Last week, the California Air Resources Board (CARB) released new data on the Low Carbon Fuel Standard (LCFS) program showing a big jump in the use of biogas from dairy farms to power vehicles.

Anaerobic digestion works by sealing manure in a giant pit to keep oxygen out while microbes feed on the contents, producing biogas as a byproduct. One of the first applications of this technology was in the late 1800s at a leper colony in Matunga, India. They captured gas from septic tanks to run a gas engine for pumping sewage, and also for lighting and cooking. Professor Gilbert Fowler took this picture of the digester for his 1934 book on biochemistry.

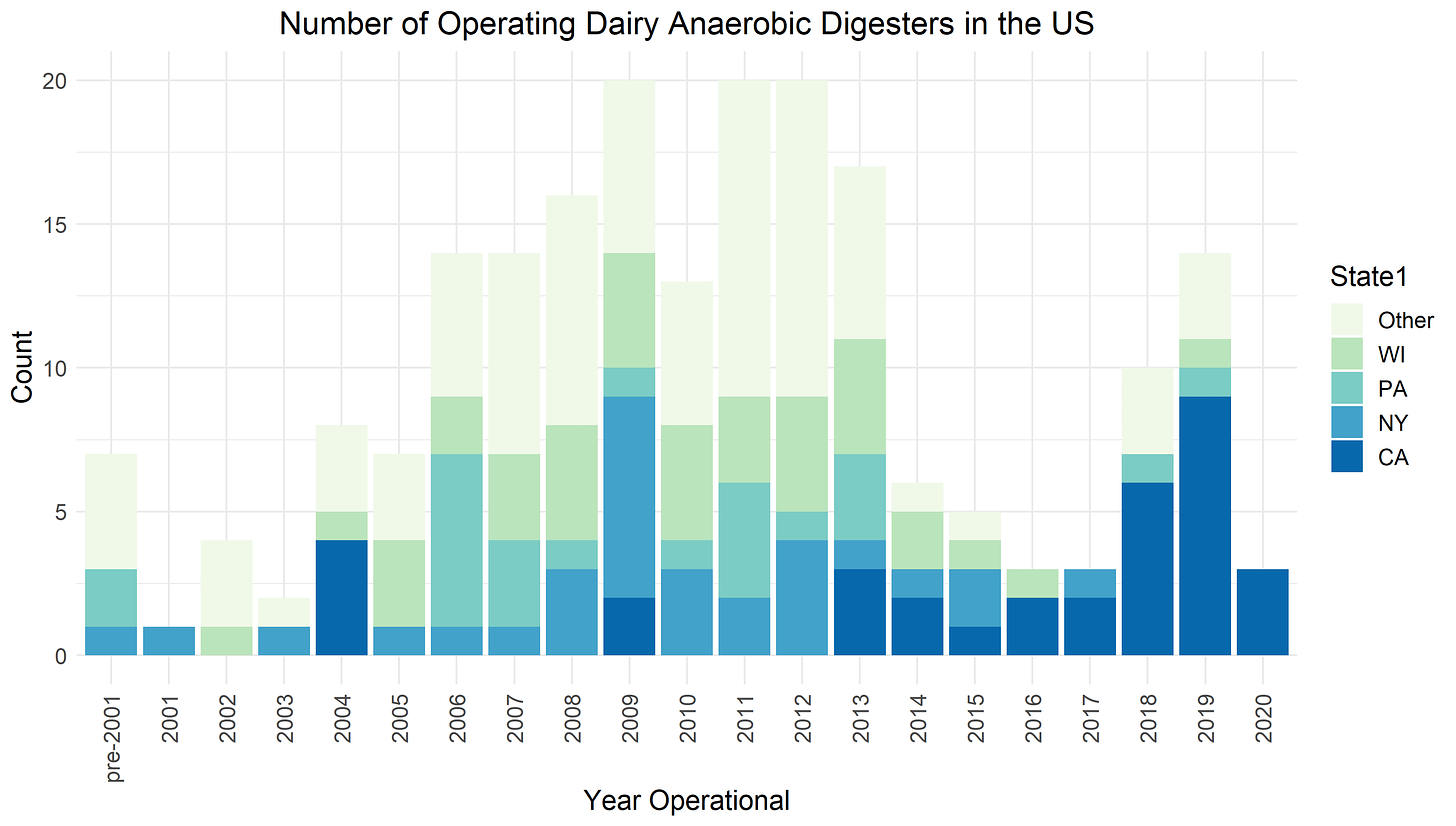

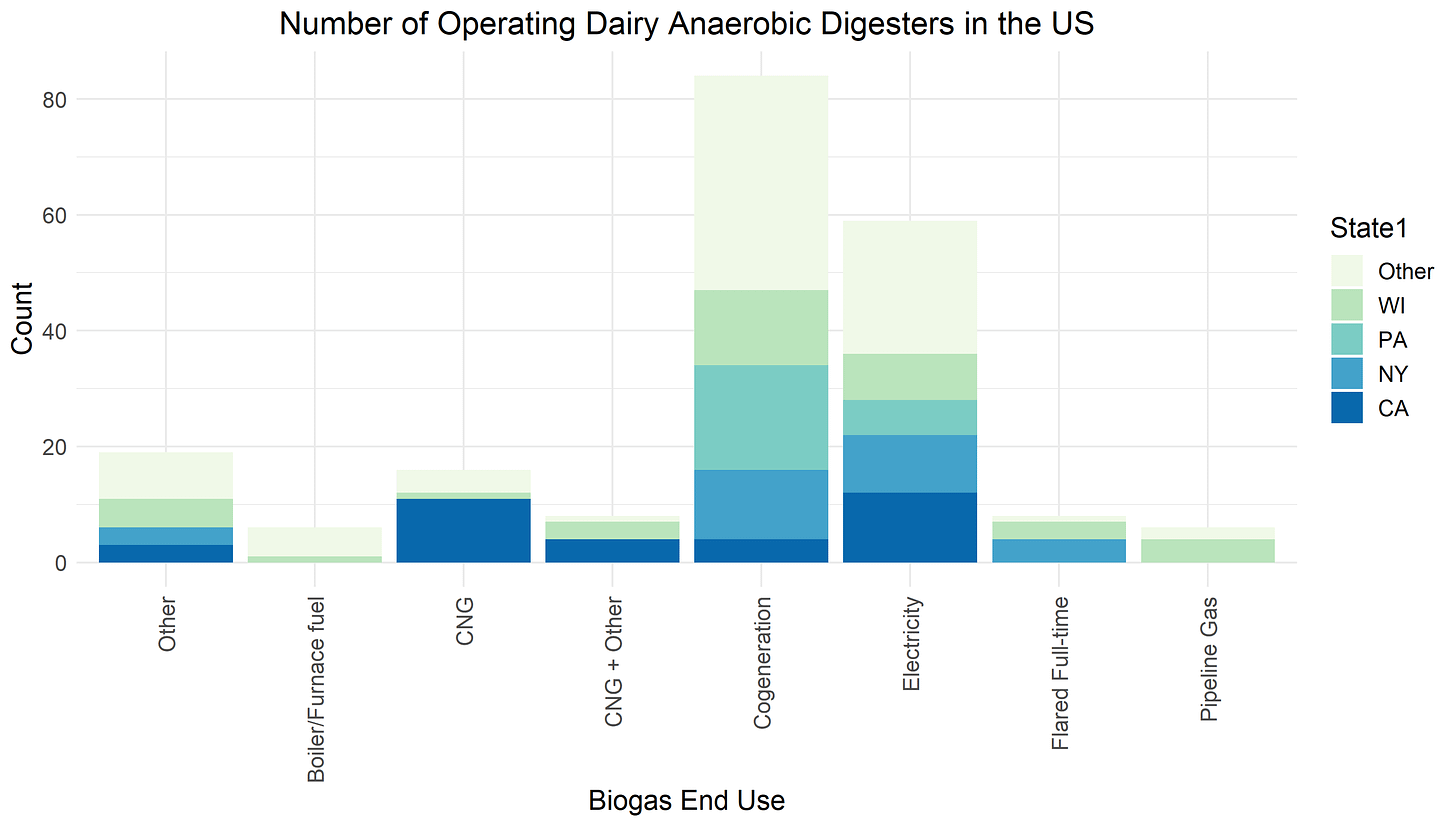

There are currently 207 anaerobic digesters operating on America's 40,000 dairy farms. Many were installed in 2006-13 in the Midwest and Northeast with Farm Bill funding through USDA's Rural Energy for America Program. In the last five years, most new dairy digesters have been in California.

Equal numbers of California digesters are employed to produce CNG for transportation and to generate electricity. Most digesters outside California produce biogas that is used to generate electricity or in cogeneration plants, which produce electricity and heat.

Anaerobic digesters are an expensive way to produce natural gas; they are about four times more expensive than pulling it out of the ground. Specifically, the spot price of natural gas is about $3 per MMBTU. Using CARB numbers, this article by my colleagues Hyunok Lee and Dan Sumner reports that a digester costs about $588,000 per year for a 2000-cow dairy, or $294 per cow. That cow generates approximately 22.5 MMBTU of gas per year, which is worth $68.

Update (2/4/21): These cost numbers exclude capital costs of installing the digester, which total $4.8m. Amortized over 10 years at 7% discount rate, capital costs equal $683,000 per year, or $342 per cow. The total annual cost of installing, running and maintaining the digester is therefore 342+294 = $636 per cow. I exclude capital costs because they are often paid by government grants rather than the farmer.

It costs $294 to get $68 worth of gas from a cow's manure.

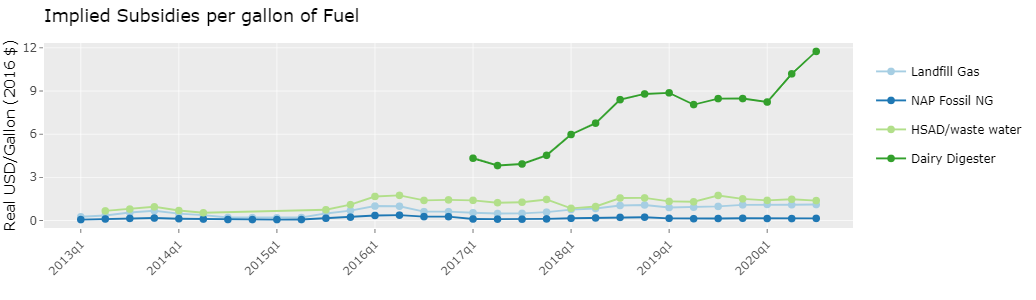

Policy incentives make it profitable for dairy farmers to install digesters. The largest such incentive in California comes through the Low Carbon Fuel Standard (LCFS), which I wrote about here and here. In the most recent quarter for which data are available, the LCFS offered subsidies of $12 per diesel-gallon equivalent, which translates to $86 per MMBTU.

Our cow generates a subsidy of $1,935 from its 22.5 MMBTU of gas per year, more than enough to cover the $294 cost of running and maintaining the digester.

Why the big subsidies? Methane is a powerful greenhouse gas, and if it were not captured, it would have been emitted into the atmosphere and caused warming. Thus, farmers are being paid to reduce their methane emissions, and they produce a little biogas for transportation as a by-product. The value is in prevented emissions.

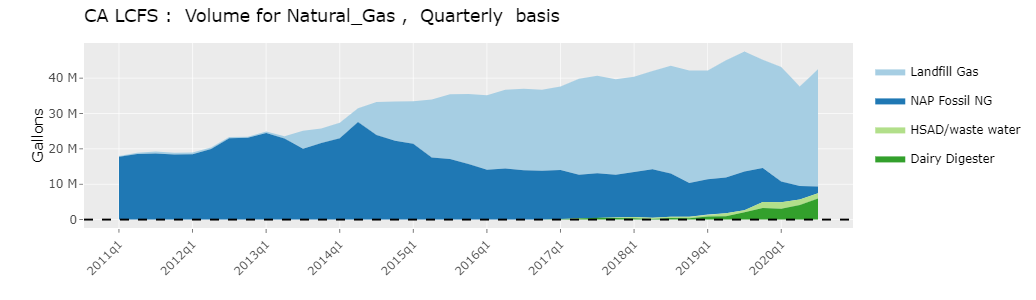

There is still considerable scope for biogas from dairy digesters to grow in the LCFS, especially given the large subsidy. In 2012, essentially all natural gas used in transportation in the state was from fossil sources. In the ensuing years, biogas from landfills drove fossil gas out of the market. Now, dairy biogas is poised to drive out landfill sources.

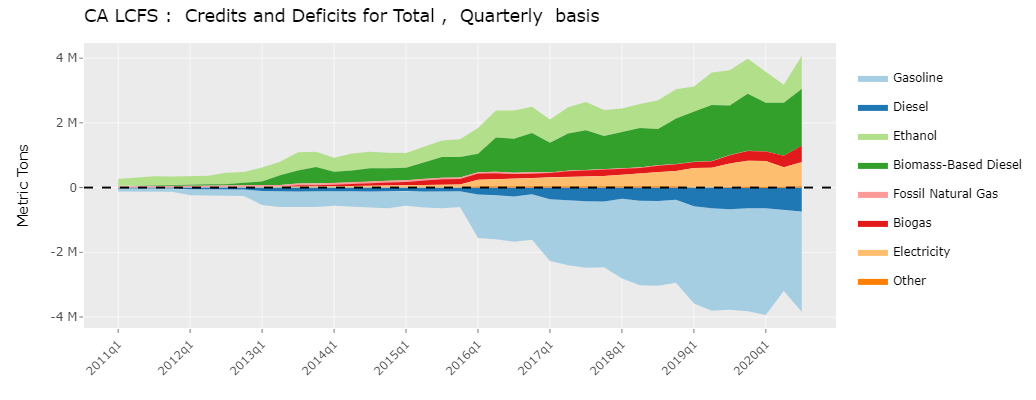

To implement the LCFS, CARB determines the carbon intensity (CI) of each transportation fuel using a life cycle analysis of the fuel pathway, accounting for potential emissions throughout the fuel production process. Gasoline and diesel incur deficits because they have high CI's (i.e., high carbon emissions per unit energy). Fuels such as ethanol, biodiesel, renewable diesel, electricity, biogas, and hydrogen earn credits because they have low CI's. The credits have to balance out the deficits.

Because it receives credit both for reducing methane emissions from manure and replacing a dirtier fuel, dairy biogas generates a subsidy 10 times higher than landfill gas. Thus, even though it accounts for only a seventh of natural gas fuel volume, dairy biogas generates more LCFS credits than landfill gas. Dairy biogas generated 330,000 MT of credits in the most recent quarter; it would generate 2.3 million credits if it were to replace all natural gas fuel.

In recent quarters, total LCFS deficits and credits have been about 4 million per quarter. If dairy digester credits were to reach 2.3 million per quarter, then it would relieve some pressure on the policy.

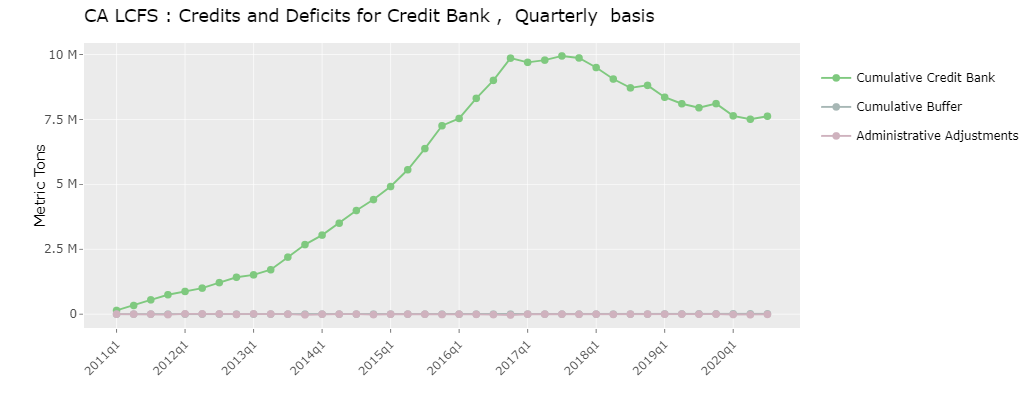

A sign that the policy has been under pressure is that the LCFS credit bank has been declining for three years. However, in the most recent quarter, the bank increased by 130,000 credits, about the same as the increase in dairy digester credits that quarter.

A typical California dairy cow produces 230 cwt of milk each year. At a price of $16.50/cwt, the cow produces $3,800 of milk per year. This is twice as much as the subsidy the cow gets from the LCFS.

So, the cow's milk is worth more than its poop, but the poop is worth a lot.

This fact should make us pause. The large subsidy is deigned to prevent methane emissions that would have happened otherwise. But, what if the farmer adds cows because of the subsidy? Then we are no longer paying to reduce emissions.

I generated the first two figures using this R code. The remainder of the figures come from our LCFS data app. Huge kudos to UC Davis ARE PhD student Dan Mazzone for his great work putting this app together and keeping it up to date.